As a leading water treatment plant manufacturer in India, GIECL is well-positioned to support the rapidly growing green hydrogen sector. Green hydrogen production relies on electrolysis, a process that requires ultrapure water to ensure efficiency and longevity of electrolyzers. Any impurities in the water can lead to scaling, reduced efficiency, and increased maintenance costs.

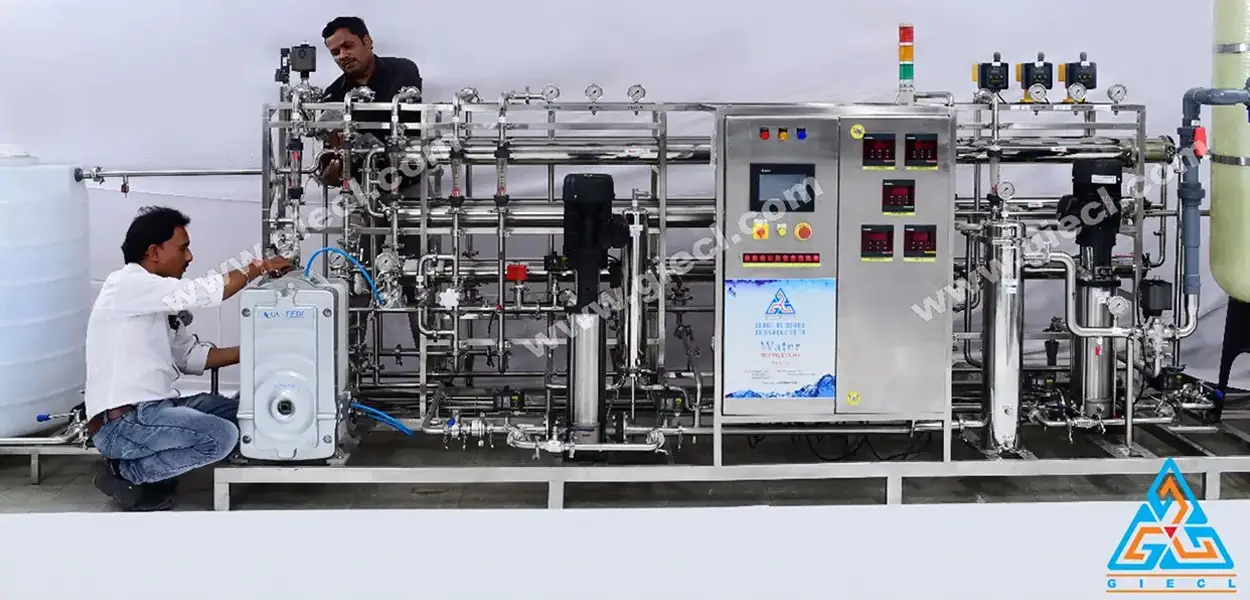

we specialize in advanced water purification and treatment systems that can be tailored to meet the stringent water quality requirements of green hydrogen plants. Our expertise in reverse osmosis (RO), deionization, ultrafiltration, and electrodeionization (EDI) ensures that the water used in electrolysis is free from contaminants such as salts, minerals, and organic matter.

Distilling Green Hydrogen Water Plant: GIECL's Potential Role

While GIECL is primarily known for its expertise in water treatment and mineral water plants, the concept of a "Distilling Green Hydrogen Water Plant" involves innovative technologies that could potentially align with their capabilities. Here's how GIECL might contribute to this emerging field: