FAQ'S Of Sewage Treatment Plant

What is sewage?

Sewage is made up of waste water from households, hotels, and may also include industrial waste water.

What are the 7 steps in Sewage treatment?

there are 8 steps of sewage treatment plants.Step 1: Screening and Pumping : Objects such as rags, wood fragments, plastics, and grease are removed from the incoming wastewater by screening equipment. The removed material is washed, pressed, and disposed of in a landfill. The screened wastewater is then pumped to the grit removal step.

Step 2: Grit Removal : Heavy but fine material, such as sand and gravel, is removed from the wastewater in this step. This waste is also dumped in a landfill.

Step 3: Primary Settling : The material, which settles at a slower rate than in step two, is removed using large circular tanks known as clarifiers. The settled material, known as primary sludge, is pumped to the tank's bottom, while the wastewater exits from the top. Floating debris, such as grease, is skimmed off the top and sent to digesters with the settled material. Chemicals are also used in this step to remove phosphorus.

Step 4: Aeration / Activated Sludge : The majority of the wastewater treatment occurs during this step. Pollutants are consumed by microorganisms and transformed into cell tissue, water, and nitrogen through biological degradation. The biological activity that occurs in this step is very similar to what occurs at the bottom of lakes and rivers, but the degradation takes years in these areas.

Step 5: Secondary Settling : At this stage, large circular tanks known as secondary clarifiers allow the treated wastewater to separate from the biology in the aeration tanks, resulting in an effluent that is now over 80% treated. In step four, the biology (activated sludge) is continuously pumped from the clarifier bottoms and returned to the aeration tanks.

Step 6: Filtration : This step polishes the clarified effluent by filtering it through 10 micron polyester media. The material captured on the surface of the disc filters is backwashed on a regular basis and returned to the plant's head for treatment.

Step 7: Disinfection : After the filtration step, ultraviolet disinfection is used to ensure that the treated wastewater is virtually bacteria-free. The ultraviolet treatment process kills any remaining bacteria to levels that are acceptable under our discharge permit.

what is process of Sewage Treatment Plant?

Sewage can be treated by designing a sewage treatment plant (STP) which involves three stages: primary/preliminary, secondary and tertiary.

Which plant is used for sewage treatment?

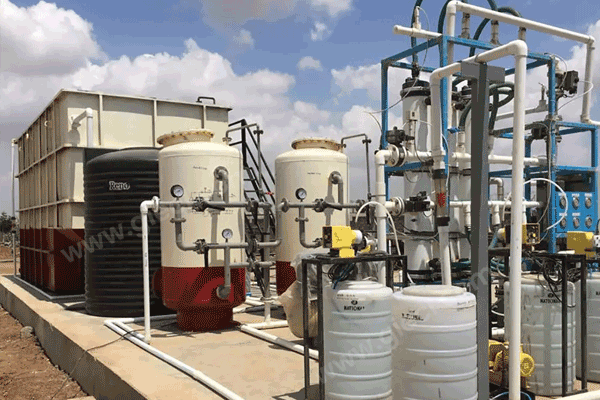

Membrane Bioreactor Sewage Plant